Heavy duty gas struts are essential components that we often take for granted in both industrial and everyday settings. From supporting the tailgates of vehicles to enabling the smooth movement of machinery, these gas struts play a crucial role in many applications where strength, durability, and smooth operation are required. In this guide, we’ll break down what heavy duty gas struts are, how they work, and where they’re used. We’ll also look at what makes them different from standard gas struts and why they’re so important in various industries.

What exactly are heavy duty gas struts?

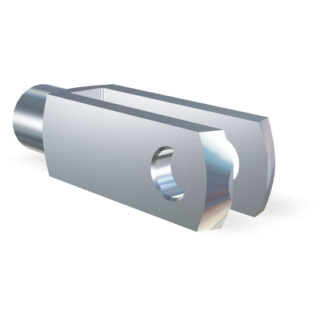

Put simply, heavy duty gas struts are devices that help lift, lower, or support heavy objects by using compressed gas within a sealed cylinder. These are the larger, more powerful cousins of the standard gas struts you might find in car boots or kitchen cabinets. Heavy duty versions are designed to handle much heavier loads and are often found in industrial equipment, large vehicles, and construction machinery. These struts use a piston and pressurised gas, typically nitrogen, to control movement. By adjusting the internal pressure, they can provide just the right amount of force needed to lift or support a load without jerking or bouncing.

How do heavy duty gas struts work?

Heavy duty gas struts operate on a simple principle: the pressurised gas inside the cylinder creates force when the piston moves. This force helps to lift or support heavy objects. Here’s a more detailed look at how they work:

- Cylinder and piston system: The gas strut consists of a cylinder filled with compressed gas and a piston that moves inside the cylinder. When the piston is pushed, the gas inside compresses, creating resistance.

- Controlled movement: The resistance created by the gas pressure allows for smooth and controlled movement. This means that whether you’re lifting a heavy hatch or lowering a large door, the movement won’t be too fast or uncontrolled.

- Adjustable force: The beauty of these struts lies in their ability to be fine-tuned. By adjusting the gas pressure, you can alter the force exerted by the strut, making it suitable for loads of different weights.

Common applications of heavy duty gas struts

Heavy duty gas struts are used across a variety of industries. Let’s look at some of the most common applications:

- Industrial machinery

In the world of heavy machinery—think excavators, cranes, and assembly lines—gas struts are essential. They provide the lifting power needed for large, heavy panels, hatches, and access doors. Without them, manually operating these heavy components would be nearly impossible. - Automotive sector

We also see heavy duty gas struts in the automotive industry, particularly in larger vehicles like trucks, buses, and agricultural machinery. They’re used to help lift and support massive tailgates, bonnets, and other large parts of these vehicles, ensuring that these components can be opened and closed smoothly. - Aerospace and marine

In the aerospace and marine sectors, where conditions can be extreme and equipment large, heavy duty gas struts play a vital role. They are commonly found in aircraft, boats, and ships, supporting heavy doors and hatches in environments where safety and durability are critical. - Construction equipment

Construction vehicles and equipment, such as bulldozers and backhoes, often rely on heavy duty gas struts to move and support their weighty parts. These struts can endure the tough conditions and heavy workloads found on construction sites. - Heavy furniture and specialised architecture

While it’s less common, heavy duty gas struts also have a place in furniture and architectural designs. For instance, they can be used in folding walls, lifting beds, or even hidden storage units. They provide the necessary strength for smooth operation in designs that involve moving heavy sections.

Key features of heavy duty gas struts

Heavy duty gas struts are built to handle more challenging tasks than their standard counterparts. Here are some of the standout features that make them ideal for heavy-duty applications:

- High load capacity: These struts are designed to bear loads that standard gas struts simply can’t handle. Depending on the model, they can support weights ranging from several hundred to several thousand Newtons of force.

- Long-lasting durability: Durability is key when it comes to heavy duty gas struts. Typically made from high-strength materials like stainless steel or carbon steel, these struts can resist the wear and tear that comes with heavy usage in harsh environments. Some models are even built to withstand corrosion and extreme temperatures, making them perfect for outdoor or high-temperature applications.

- Customisable force: One of the best features of heavy duty gas struts is their adjustability. By fine-tuning the internal pressure, you can customise the amount of force the strut generates, allowing you to match it perfectly to the load it needs to support.

Selecting your gas strut

Selecting the right gas strut for your specific needs can make a significant difference in performance and longevity. Here are some things to consider when choosing the right heavy duty gas strut:

- Weight of the load

You’ll need to know exactly how much weight the gas strut needs to support. Choosing a strut that isn’t powerful enough could lead to performance issues or even safety risks. Always check the load rating of the strut to ensure it matches your requirements. - Stroke length

The stroke length of a gas strut refers to how far the piston can extend or retract. Make sure you choose a strut with a stroke length suitable for the movement needed in your application. - Working environment

Some environments are particularly tough on equipment, so it’s essential to select a gas strut that’s designed to handle those conditions. If the strut will be exposed to harsh weather, high temperatures, or corrosive environments, make sure the strut is made from materials that can withstand these factors. - Material and finish

Gas struts are available in various materials, such as aluminium, stainless steel, or carbon steel, and finishes like zinc plating. The material and finish can affect the strut’s performance, especially in terms of durability and corrosion resistance. - Installation fit

Ensure that the gas strut is compatible with the mounting and installation setup of your system. It’s essential to match the mounting brackets and fittings to avoid any installation challenges.

Maintaining your heavy duty gas struts

Even though heavy duty gas struts are built to last, proper maintenance is crucial to extend their lifespan and ensure they continue performing well. Here are a few tips for maintaining your gas struts:

- Regular cleaning: Keep the gas struts clean and free from dirt, dust, and debris that could impair their function.

- Lubrication: Make sure that any moving parts are regularly lubricated to prevent unnecessary friction and wear.

- Routine inspections: Periodically check for signs of wear, leaks, or other damage. Early detection of problems can save you from costly repairs or replacements down the line.

- Follow manufacturer’s guidelines: Always refer to the manufacturer’s recommendations for proper usage and maintenance to ensure your gas struts perform optimally.

Can heavy duty gas struts be used for vertical and horizontal loads?

Heavy-duty gas struts can support both vertical and horizontal loads, but how well they work depends on the installation and application. In vertical use, like car hoods or machinery doors, they often benefit from gravity, helping to lift or lower objects smoothly. In horizontal setups, such as sliding panels, they work purely on internal pressure, so alignment is key to avoid wear and ensure smooth operation. It’s important to choose struts with the right load capacity and mounting orientation for longer life, and some models even offer motion control for a gentler opening or closing.

What are the environmental conditions in which these struts can operate?

Heavy-duty gas struts are designed to operate in a wide range of environmental conditions, typically handling temperatures between -30°C to 80°C, though some specialised models can function in even more extreme temperatures. Humidity isn’t usually a major concern, as gas struts are sealed systems, but prolonged exposure to highly humid or corrosive environments can affect their lifespan unless they are coated or made with corrosion-resistant materials. It’s always best to check the manufacturer’s specifications for specific environmental limits, especially if they’re being used in challenging settings like marine or industrial applications.

How does the strut behave in case of gas leakage or failure?

In the event of gas leakage or failure, a heavy-duty gas strut will lose its ability to provide the necessary support and resistance. As the pressurised gas escapes, the strut’s internal pressure drops, reducing its ability to extend or hold weight. This can result in the strut collapsing or failing to operate smoothly, making it harder to lift or hold objects in place. Essentially, the strut will feel weak or sluggish, and in more severe cases, it may completely lose its function, causing a safety hazard if relied upon for holding heavy objects. Regular checks can help detect early signs of leakage or failure.

Use our online tools to find the perfect gas struts

In our webshop, you’ll discover a diverse selection of gas struts for heavy-duty applications. Navigate to products in the header and choose between steel or stainless steel gas struts; from there, filter by size. If you’re unfamiliar with the force needed for your project, use our calculator tool.

Calculator tool

Our calculator tool allows you to determine the force needed for smooth operation and the appropriate location to mount your heavy-duty gas struts. After using the tool, you’ll receive suggestions for gas struts that perfectly fit your application.

Replacement tool

Looking to replace your old heavy-duty gas struts? Use our replacement tool by entering (part of) the article number found on the old strut. Click the suggested product, verify the match, and complete your order in a few simple steps.

Configurator tool

For those familiar with the force in Newtons needed for smooth project operation, our configurator tool allows full customization of a gas strut. Switch between gas springs, materials, and mounting parts in an interactive interface. Choose the required force in Newtons, add to your cart, and order easily.

Order your heavy duty gas struts today

Heavy duty gas struts are indispensable in numerous industries, from construction and automotive to aerospace and beyond. Their ability to handle heavy loads with smooth, controlled motion makes them a crucial component for many applications. By choosing the right gas strut for your specific needs and ensuring proper maintenance, you can count on them to provide reliable performance and durability over the long term. Our products are shipped from the UK within 1-2 business days. Utilize our tools to calculate your application, find replacements, and customize gas struts to your requirements. Navigate to products in the header on our website to filter down by materials and size. For any unanswered questions, feel free to contact our support team at [email protected] or call +44(0)24 7645 5580 anytime.