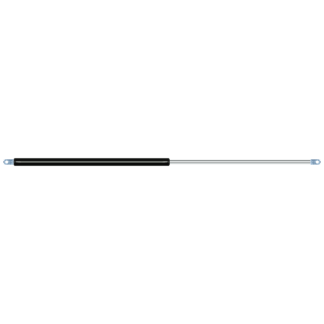

Gas springs are essential components in various applications, ranging from automotive to industrial machinery. They provide controlled motion, dampening, and support in mechanisms where traditional mechanical springs might not suffice. Understanding the intricacies of pistons and rods in gas springs is crucial for optimising their performance and longevity.

The role of pistons in gas springs

Pistons are the core components that facilitate the conversion of gas pressure into linear motion. Typically made from high-strength materials such as steel or aluminium, pistons are engineered to withstand substantial pressure differences.

Material and design

The design and material of pistons are paramount to their functionality. High-grade steel and anodised aluminium are common due to their strength and resistance to wear. The piston’s seals ensure minimal gas leakage, maintaining the spring’s pressure and performance over time. Advanced designs may incorporate multiple seals to enhance durability and efficiency.

Functionality

The piston divides the gas spring into two chambers, with a **valve system** allowing controlled flow of gas between them. This controlled flow regulates the **damping characteristics**, ensuring smooth and consistent operation. The piston’s movement is crucial for applications requiring precise positioning and smooth motion control.

Understanding rods in gas springs

Rods are equally vital as they transmit the force exerted by the gas spring to the external mechanism. The rod’s strength, coating, and finish significantly impact the gas spring’s performance and lifespan.

Material and coatings

Rods are typically manufactured from hardened steel or stainless steel, chosen for their high tensile strength and resistance to bending. Chrome plating is a common coating, providing a smooth surface that reduces friction and wear. Nitride coatings are also used for their superior durability and corrosion resistance.

Critical dimensions

The diameter and length of rods are critical dimensions influencing gas springs capacity and force output. A larger diameter rod can handle greater loads, while the length determines the stroke and overall size of the gas spring.

Interaction between pistons and rods

The interaction between pistons and rods is the heart of a gas spring’s operation. This relationship determines the efficiency, force, and smoothness of the gas spring’s action.

Sealing systems

A robust sealing system is essential to maintain the internal pressure and prevent gas leakage. High-quality seals, often made from synthetic rubber or PTFE, ensure longevity and reliability. These seals must endure high pressures and temperatures without degrading.

Guidance and alignment

Proper guidance and alignment of the rod within the cylinder are crucial. Misalignment can lead to increased wear and tear, reducing the lifespan of the gas spring. Precision-engineered guide bushings are employed to maintain alignment and reduce friction.

Applications of gas springs with pistons and rods

Gas springs find applications across various industries, each demanding specific performance characteristics.

- Automotive industry

In the automotive sector, gas springs are used in applications such as boot lids, bonnets, and tailgates. The ability to provide controlled, smooth motion and support is essential for user safety and convenience. - Furniture and ergonomics

Gas springs are integral to adjustable furniture, such as office chairs and ergonomic desks. They allow easy adjustment and positioning, enhancing comfort and usability. - Industrial machinery

In industrial settings, gas springs are used in machine guards, hatch covers, and tooling equipment. Their reliability and ability to handle heavy loads make them indispensable in maintaining operational efficiency and safety.

Maintenance and troubleshooting

Proper maintenance ensures the longevity and optimal performance of gas springs.

Regular inspection

Regular inspection of the gas spring’s seals, rod surface, and mounting points is essential. Any signs of wear, corrosion, or misalignment should be addressed promptly to prevent failure.

Lubrication

Ensuring adequate lubrication of the rod and seals can significantly reduce friction and wear. Use lubricants recommended by the manufacturer to avoid compatibility issues.

Troubleshooting common issues

Common issues include gas leakage, reduced force output, and noisy operation. Identifying the root cause, such as a damaged seal or misalignment, and taking corrective action can restore the gas spring’s performance.

Choosing the right gas spring

Would you like to order gas springs? We assure a seamless shopping experience with the help of our online tools, designed to assist you in choosing the best option for your specific task.

-

- Calculator tool

What type of gas spring do you need? Determining the correct size and strength can be challenging. This is where our calculator tool comes in. Simply input parameters such as length, width, weight, pivot point, angles, and more, and the tool will guide you, recommending the best gas powered struts for you. - Replacement tool

Over time, your once-efficient gas strut may lose its effectiveness. For situations where safety is crucial, prompt gas spring replacement is essential. Our replacement tool simplifies this process, helping you quickly identify equivalent replacements for popular gas strut brands. Enter the product number, select the recommended product, verify, and order with ease. Begin your search for the ideal gas struts with our replacement tool. - Configurator tool

For those who enjoy customization, the configurator tool is the best solution. Its interactive platform allows you to choose materials, switch between measurement units, and select mounting options and gas spring types. You can even preview a 3D model. Afterward, specify the necessary force in Newtons (calculated via the calculator tool). Once completed, add your custom gas strut to your cart and proceed to checkout.

- Calculator tool

Order your gas springs at Gasspringsshop

Would you like to use a gas spring? Order your gas struts online at gasspringsshop.co.uk. Any questions? Our support team is always ready to assist. Contact us via email at [email protected] or call us at +44(0)24 7645 5580.