If you’ve just installed a new gas strut and it won’t compress, you’re probably feeling frustrated. Gas struts – the mechanisms that smoothly lift and lower things like car boots, hatches, and cabinet doors – should work with ease. But sometimes, even a brand new gas strut won’t compress, which can be confusing and inconvenient. In this guide, we’ll walk through what might be causing this problem, simple troubleshooting tips, and a few handy solutions to get your new gas strut working smoothly.

How gas struts are meant to work

Gas struts, sometimes called gas springs, contain compressed gas (usually nitrogen) and a bit of hydraulic oil in a sealed cylinder. They create pressure to help lift or hold a door or lid in place. When working correctly, a new gas strut should compress smoothly as you push on it. If it doesn’t, there could be several reasons why. Here’s a breakdown of some of the common causes.

Common reasons your new gas strut won’t compress

- High-pressure charge: Gas struts are pre-loaded with gas, which is what allows them to bear weight. Sometimes a strut can come with higher-than-expected pressure, making it harder to compress. This often happens with struts made for heavy-duty use, and they may just need a firm initial push.

- Incorrect installation angle: Gas struts need to be installed in a specific orientation, with the right angle and positioning. If they’re installed at the wrong angle, the strut won’t compress as it should.

- Locking mechanisms: Some gas struts are made with a lock that prevents them from moving unless a specific condition is met. For instance, a lock could stop the strut from compressing unless you press a release button or twist the rod.

- Temperature issues: If your new gas strut has been in a very cold environment, the gas inside can contract, affecting how well it compresses. Usually, this is a temporary issue, but it can be surprising if you’re using the strut for the first time.

- Manufacturing faults: It’s rare, but a manufacturing defect could be the cause. Problems like a leak or internal misalignment can prevent the strut from working as it should.

Step-by-step troubleshooting guide

Your new gas strut won’t compress? Here are a few ways to identify the issue and hopefully get your gas strut working as expected:

- Check the installation

First, confirm that the new gas strut is installed correctly. Most gas struts are designed to be installed with the rod end pointing down when at rest. This positioning allows the oil to flow into the seal and maintain a smooth operation. Installing it the wrong way up or at an unusual angle can stop the gas strut from compressing properly. - Apply gentle pressure

If your strut seems to have a high-pressure charge, you may just need to apply a bit of extra force at first. Hold the strut securely and press down gently but firmly. Be cautious not to use too much force, as it could damage the strut or injure you. - Look for a locking mechanism

Some struts have locking features that need to be disengaged before they can compress. Check the product manual to see if your gas strut includes a lock, and follow the instructions to unlock it. This is especially common in struts designed for furniture or medical equipment, where safety locks are essential. - Check for temperature issues

If your new gas strut has been stored in a very cold place, let it warm up to room temperature before trying it again. The gas inside expands in warmer temperatures, which may resolve the compression issue. - Inspect for defects

Look over the gas strut for any visible signs of damage, such as dents or leaking oil. If you can’t identify the issue and it still won’t compress, it may be defective. In that case, consider contacting the manufacturer for a replacement.

Different types of gas struts and how they work

Gas struts come in several types, each suited to different uses. Knowing which type you’re working with can help with troubleshooting:

- Standard gas struts: These are the most common and offer simple, consistent support. They are generally ready to go out of the box and only need routine checks for wear.

- Locking gas struts: Ideal for applications where you need to hold a position, these struts have locks that you need to disengage before compressing.

- Adjustable gas struts: Some struts allow pressure adjustments to handle various loads. These should only be adjusted following the instructions, as incorrect pressure can damage them.

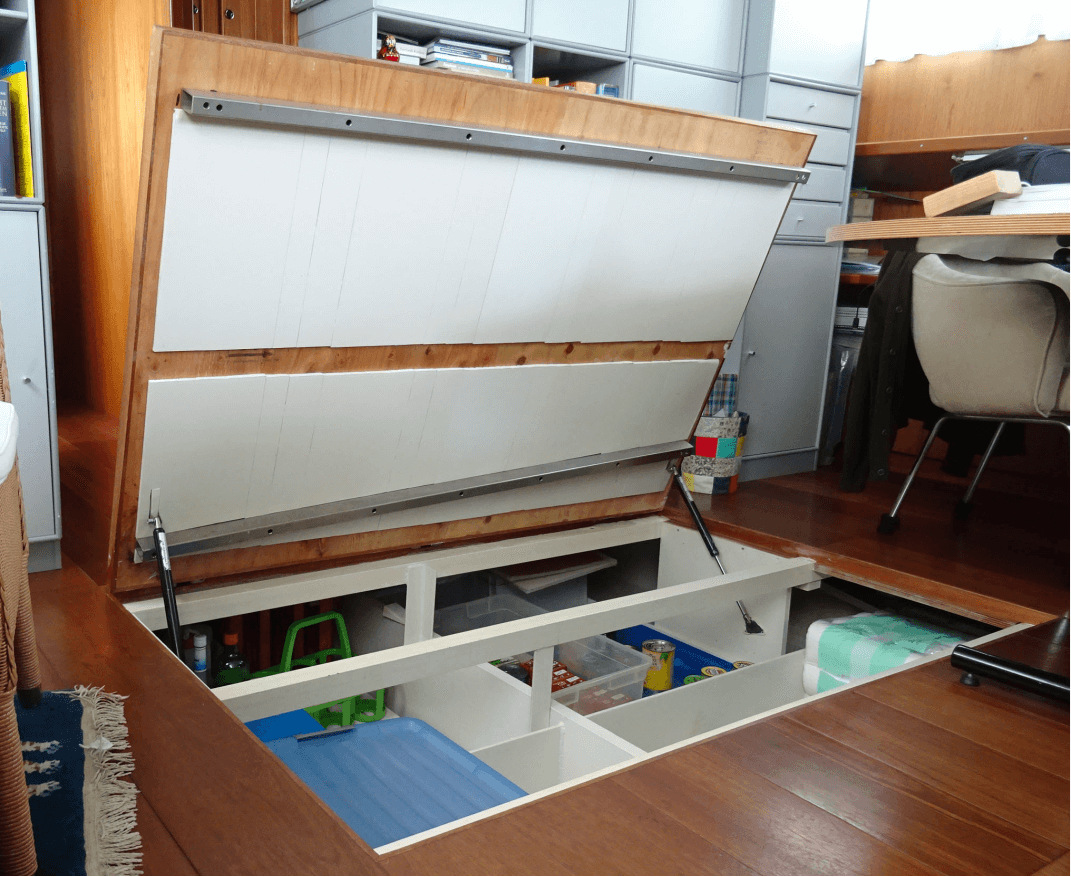

- Heavy-duty gas struts: Made for handling heavier weights, these have high gas pressure and may need extra initial force. They’re typically used in machinery or large storage hatches.

Tips for maintaining gas struts

Taking care of your gas struts will help them last longer and prevent issues. Wipe down the strut regularly with a soft cloth to remove any dirt or grime. Gas struts rely on a sealed gas chamber to operate. Periodically check for oil leaks or unusual noises, as these could indicate an issue.

For some gas struts, a small amount of lubrication can help reduce friction. Always check the manufacturer’s advice on lubrication, as overdoing it can attract dust and debris. If you have spare gas struts, keep them in a moderate temperature range. Extreme temperatures can impact their performance. Eventually, even well-maintained gas struts wear out. When they start losing pressure or show signs of wear, consider replacing them to avoid failures.

Order your new gas struts at Gasspringsshop!

Our gas struts are shipped from the UK and typically arrive within 1-2 business days. Use our online tools to calculate your application, find replacements, and customise gas struts to your specific needs. To explore products, simply go to the header on our website, where you can filter options by material and size. If you have any questions, our support team is here to help– just email us at [email protected] or call +44(0)24 7645 5580 at your convenience.